Speaker

Description

Abstract— In this work, a new topology of an inductor of axial flux synchronous machine is presented and tested. It is executed by combining superconducting (SC) bulks and six solenoids. It consists of six superconducting solenoids connected in series stuck in a non-magnetic disc and supplied by direct current. The presence of two SC bulks which by their magnetic field screening property, modulate and redirect the flux density lines produced by the six solenoids . Thus, we can generate a periodic spatial variation of the axial flux density component.

A 3D Electromagnetic modeling based on finite elements solution is developed to demonstrate the suitability of using the magnetic shielding properties of the SC bulks. In order to check the screening properties of the SC bulk, a prototype of the proposed inductor has been constructed at the laboratory. it consists of six copper solenoids and two circular shape superconducting YBCO bulks.

Keywords—Axial machine, Magnetic Field concentration,Superconducting Inductor, Superconductor machine.

I. INTRODUCTION

The advances in the technology of superconducting materials and cryogenic systems are at the origin of a new generation of electric actuators. Indeed, the use of superconductors allows to generate very intense magnetic fields and to transmit energy without losses 1.

One of the main challenges to use of superconductors in electrical machines is increasing the flux density in the air gap and therefore reduces the volume of the electrical machine 3.

Various topologies of synchronous machines have been realized with inductors excited by superconductor coils. In synchronous machines with axial flux, the magnetic field is directed along the axis with "flower petal" windings. Several structures have been realized, distinguishing three categories, machines with superconducting coils, others with passive superconducting materials (bulks) and machines with both types of the materials [1,5].In this work, a new topology of an inductor of an axial-field synchronous machine is presented and constructed in the laboratory. It is executed by combining SC bulks and solenoid. This inductor, as shown in figure.1, is made up of six superconducting solenoids connected in series stuck in a non-magnetic disc supplied by direct current. The presence of two SC bulks which by their magnetic field screening property, modulate and redirect the flux density lines produced by the solenoids [5,6].Thus, we can generate a periodic spatial variation of the axial flux density component. In fact, each HTC superconducting bulks placed on the non-magnetic disk (inductor) cooled with liquid nitrogen constitutes a barrier against the passage of the flux density lines created by the superconducting solenoids [4,2].

II.ELETROMAGNETIC MODELING

In order to study the feasibility of this new topology inductor of synchronous machine, a 3D Electromagnetic modeling based on finite elements solution is developed. The model was solved in magneto-static without induced currents. Using a magnetic vector potential formulation, noted A, the flux density B is defined by:

B = ∇×A....................................(1)

The PDE to solve in the different regions parts of the inductor is:

In the air and the superconducting bulks: ∇A^2 = 0..........(2)

In the solenoid: ∇A^2 = -μ0 μrJ.............................(3)

It is considered in this modeling that the superconducting solenoids is supplied by a uniform current density across their sections area and low relative permeability μr=10^(-4) of the SC bulk to take into account its screening property.The magnetic potential is taken as zero on the surfaces of a box encompassing the structure of the inductor and the armature.

The developed 3D elements finite model is simulated for the proposed inductor with superconducting solenoids supplied by DC current with a density of 743.17 A/mm2.

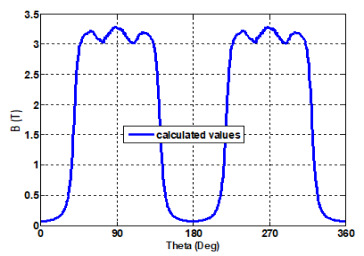

It can be seen in figure .2 that the axial flux density component predicted by the 3D developed model has a periodic spatial variation and its amplitude varies between positive Bmin and Bmax values. The maximum value reaches 3.3T.

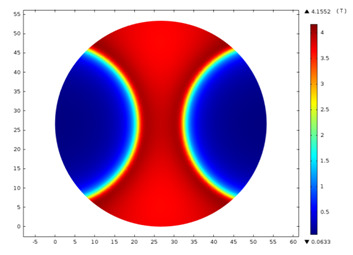

In figure .3, we can clearly see the screening effect of the two SC bulks.

III. EXPÉRIMENTAL RESULTS

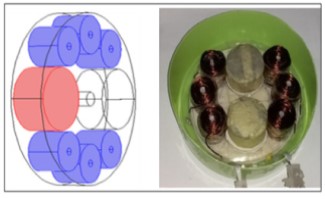

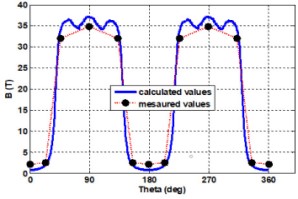

A prototype of the proposed inductor has been constructed in the laboratory. As shown in Fig. 4, it consists of six solenoids connected in series with the copper and two circular shape superconducting bulks.The SC bulk is made from YBCO material. The critical temperature of this superconductor is 93K. This inductor is cooled with liquid nitrogen to 77K.The test is carried out by supplying the solenoid with DC current of I=8.45 A. It can be seen in figure.5 that the flux density waveform predicted by the 3D developed model is in a good agreement compared to the experiments.The maximum of flux density measured in the air gap reaches 36.8 mT.

IV CONCLUSION

A new topology of an inductor of axial flux synchronous machine is presented in this work. It consists of superconducting solenoid supplied by direct current and two superconducting bulks which by their magnetic field screening property, allows to generate a periodic spatial variation of the axial flux density component.

A prototype of the proposed inductor consisting of a copper solenoid and two superconducting YBCO bulks has been developed and constructed in the laboratory.

The results obtained by 3D FE and experiments are in good agreement and they show the feasibility of the new topology of the proposed inductor. Thus, with superconducting solenoid it is possible to considerably increase the fluxdensity in the air gap and therefore reduce the volume of the electrical machine.

REFERENCES

1 EH. Ailam, MN. Benallal, M. Hachama, J. Leveque and A. Rezzoug, "Comparison Study Between Several Solutions of Superconducting Inductors," in IEEE Transactions on Applied Superconductivity, vol. 23, non. 1, pp.5200506-5200506, février 2013.

2 M. Kelouaz, Y.Ouazir and L. Hadjout, "3D Magnetic field modeling of a new synchronous machineusingnetwork method reluctance"Physica C: Superconductivity and its Applications, Volume 548, Mai 2018.

3 K. F. Goddard, B. Lukasik and J. K. Sykulski, "Alternative Designs of High-Temperature Superconducting Synchronous Generators," in IEEE Transactions on Applied Superconductivity, vol. 19, no. 6, pp. 3805-3811, Dec. 2009.

4 R. Alhasan,T. Lubin , J. Leveque , Study and test of a new superconducting inductor structure for a synchronous machine, in: International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Tunis, 2014, pp. 1–7. 3-6 Nov.

5 P. J. Masson, C. A. Luongo “High Power Density "Superconducting Motor forAll-Electric Aircraft Propulsion", IEEE Transactions on Applied Superconductivity, Volume15, Issue 2, Part 2, June 2005 Page(s):2226 – 2229.

[6] D. Netter, J. Leveque, E. Ailam, B. Douine, A. Rezzoug and P. J. Masson, "Theoretical study of a new kind HTS motor," in IEEE Transactions on Applied Superconductivity, vol. 15, no. 2, pp. 2186-2189, June 2005.

| Topic | Innovative methods and tools for modelling large-scale HTS systems |

|---|